I’ve enjoyed reading through this thread – I’ve gone through it several times and pick up something new each time. Thanks

Rocket Ray and others for sharing your expertise. I’ve just gotten into Q40 this year and I know I have a

LOT to learn. It's very humbling to have been in the RC hobby for about 45 years now (I'm 53 years of age) including four years of pylon racing, but to still have so much to learn in this new venue. But I’m loving every second of it. So now, if it’s okay, I’d like to post what’s been going on with my Nelson engine to see if I’m on the right track. I think everything is great with the engine, but I welcome advice and opinions.

I purchased the engine new this summer from Mike Langlois. Initial runs were in my Too Sweet on the ground with a 7.4 x 7.7 cut down to 6-1/2" as recommended to me. I blew the plug on the first run and here’s what the plug and exhaust looked like...

- break-in plug.jpg (23.14 KiB) Viewed 2129 times

It's perplexing because the oil was dark, but the plug had no color. In retrospect, knowing I knew nothing back then and know more now, I'd guess the exhaust residue is too dark and maybe it was lean that run? The plug was blown, so I put in a new one and ran the engine again. This time the oil was pretty much clear.

I ran it on the ground three more times the same way for a total of five ground runs.

With the assistance of a couple other Q40 pilots needling the engine for me I flew the plane in practice at the race down in Wichita – probably about eight flights total. But I had to shut it down at least a couple of times because the plane was making a strange vibration sound. One of those times I actually thought the engine quit because the plane had suddenly slowed so much. The plug was dark brown on the OUTSIDE from two of those runs. So I put the engine away and borrowed an engine from Lonnie Finch. That seemed to cure the mysterious vibration noise for a while, but it seemed to come back. The plane is history now anyway.

I removed the head and found it to be peppered. I know the guys who were needling the engine for me know what they were doing, but there was something with that plane that just didn’t agree with the engine, or vice-versa.

I returned the engine to Mike Langlois and he honed the cylinder and installed a new piston and head. It's set at .190/.018. Mike said with the previous runs I had on the engine it was basically broken in.

I then installed the engine in my new Sweet Vee. This time I added about 3 oz. of castor oil to about ¾ gallon of fuel (first time the engine had been run with added castor). I got some advice from another trusted source to do the first launch for the maiden at about 23,000rpm I think it was. I was on my own, so it was time to be a big boy and needle the engine myself.

I didn't want to damage the engine and I wanted to stay far away from anything even resembling a lean run, so I started out very conservatively and launched it around 21.5K. It was nearly hitting the pipe on the ground, so I figured it would come on the pipe in the air. All was well, the engine was great, but I could tell it was rich. The plane flew well and all was normal—no mysterious buzzing noise and the engine sounded good. I flew it five times that day. For the last flight I put in a new plug so I could get a good reading and launched it at around 24K. The plane seemed fast to me and sounded good. I was concerned I launched it a little high on the rpm, but when I came down and looked at the plug it looked good – possibly a little too much color, but okay I think. This is the plug after that flight...

This was also before I learned about reading the pitch of props which I am now doing. I measured the pitch later and it came out to 7.0 (it's a 7.4 x 7.5). A few others I've measured come out to like 6.875, so maybe that 7.0 is a slightly “heavy” prop.

This past Sunday I put the Sweet Vee up three more times – same fuel (with some castor) and same 7.4 x 7.0 prop. First flight I launched at about 24,000rpm. The plug is the same as the one pictured above with the one previous flight also launched at about 24K. Here's the plug after its second flight, first one of this day...

I put in a brand new plug and launched at about 23,500rpm. Another great flight. Much less oil on the bottom of the plane and it was cleaner. Plug had almost no color at all....

Continued in next post...

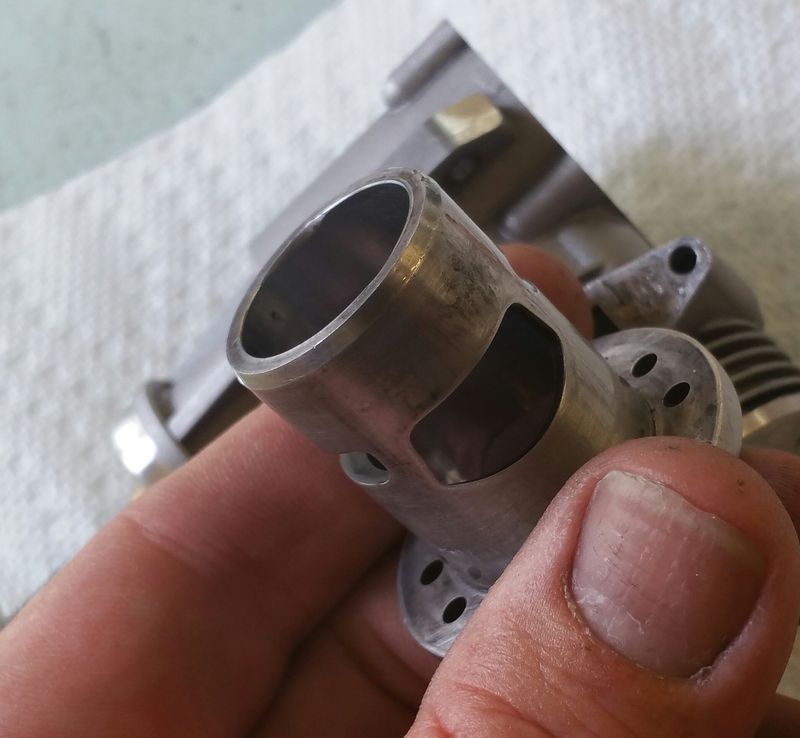

some thin CA in the cracks fixed the leaking. Next was the cylinder. It was fast before the explosion so using it again was definitely worth the fix. The case was scratched when removing the cylinder but test fitting a different cylinder proved ok so no work needed there. The cylinder was oblong from the rod beating it to death so lots of sanding on the two sides to get it back round enough to fit the case. Next was the inside bottom of the cylinder. Some small files and 320 made quick work of the burrs so the piston could pass with out obstruction.

some thin CA in the cracks fixed the leaking. Next was the cylinder. It was fast before the explosion so using it again was definitely worth the fix. The case was scratched when removing the cylinder but test fitting a different cylinder proved ok so no work needed there. The cylinder was oblong from the rod beating it to death so lots of sanding on the two sides to get it back round enough to fit the case. Next was the inside bottom of the cylinder. Some small files and 320 made quick work of the burrs so the piston could pass with out obstruction.

next was the backplate. The rod damaged was not too bad so a little filing to the edges of the case it fit back no problem.

next was the backplate. The rod damaged was not too bad so a little filing to the edges of the case it fit back no problem.  . After sanding most of the plier marks from the big flange and a final cleaning and re assembly it's living proof you can still break a minute with another's man's trash.

. After sanding most of the plier marks from the big flange and a final cleaning and re assembly it's living proof you can still break a minute with another's man's trash.