In case you haven't heard we're all voting for you as a write-in. You're not getting off that easy.kane wrote: DK

(ONLY ONE MORE WEEK OF BEING THE NMPRA PREZ!!!)

Latest and greatest timing and deck height?

Re: Latest and greatest timing and deck height?

And I said, here am I send me.

Re: Latest and greatest timing and deck height?

Don't think of it as involuntary servitude ... think of it as a personality cult. I've already ordered you a 30-foot bronze statute from Amazon. Tracking says it'll be there tomorrow.

Tied for 1st going into Round 1

-

Kurt Bozarth

- Super Contributor

- Posts: 253

- Joined: Sat Jan 25, 2003 12:36 pm

- Location: Aurora, Colorado

Re: Latest and greatest timing and deck height?

To Mr. Rocket R.,

The information you provided worked incredibly well! I reset the two used motors that were running poorly to your suggested settings and they both ran outstanding. EXACTLY what I was looking for - getting them back to close to stock, easy and predictable needling, and descent Rpms. THANK YOU for sharing your engine expertise! And thank you to all the others who added great info to the thread. My wife now has her work cut out for her in checking and resetting my other engines.

Kurt Bozarth

The information you provided worked incredibly well! I reset the two used motors that were running poorly to your suggested settings and they both ran outstanding. EXACTLY what I was looking for - getting them back to close to stock, easy and predictable needling, and descent Rpms. THANK YOU for sharing your engine expertise! And thank you to all the others who added great info to the thread. My wife now has her work cut out for her in checking and resetting my other engines.

Kurt Bozarth

Kurt Bozarth

kbozarth01@gmail.com

kbozarth01@gmail.com

Re: Latest and greatest timing and deck height?

Back a few pages, Randy Bridge asked what harm was there in skipping the G-10 material and just gluing the aluminum mount directly to the fuselage. My first thought was the ability of aluminum to transfer heat, and the affect that heat would have on the glue joint directly to a glass/carbon fuselage shell. The use of G-10 acts as a plenum does on a car engine, where a non-metallic material is placed between the engine's intake manifold and the carburetor(s). Carbs run best when kept cold, so the plenum insulates between the 2 parts. Same goes for the G-10 insulating the glue joint from the hot motor mount. Go get'em Ray at the Championship race!! Steve Baker

Re: Latest and greatest timing and deck height?

Thanks steve, but, I didn't make the trip. I'm passing the torch on Sunday.

And I said, here am I send me.

Re: Latest and greatest timing and deck height?

Steve, these motors are cooled by intake fuel on the bottom end and air on the topend. The circuit board adheres to epoxy better than aluminum and has nothing to do with cooling or insulation.

Alex, the fits of the piston and liner have to do with expansion when the parts are at operating temps. Ideally you want the piston to seal when hot at the opening of the exhaust port on the way up, at the same time you don't want it still biting as it passes the exhaust port on the down stroke. This extra friction is detrimental to rpm and horsepower.

The "ramp" is witchcraft. Some believe it's a benefit and will give you an edge, some think it's a flying broom. Me... ehhh, I wouldn't know if it's there or not unless I looked. To qualify that, in FAI I've seen stock motors go 55 sec and fully worked motors with ramps go 55 sec.

Alex, the fits of the piston and liner have to do with expansion when the parts are at operating temps. Ideally you want the piston to seal when hot at the opening of the exhaust port on the way up, at the same time you don't want it still biting as it passes the exhaust port on the down stroke. This extra friction is detrimental to rpm and horsepower.

The "ramp" is witchcraft. Some believe it's a benefit and will give you an edge, some think it's a flying broom. Me... ehhh, I wouldn't know if it's there or not unless I looked. To qualify that, in FAI I've seen stock motors go 55 sec and fully worked motors with ramps go 55 sec.

And I said, here am I send me.

Re: Latest and greatest timing and deck height?

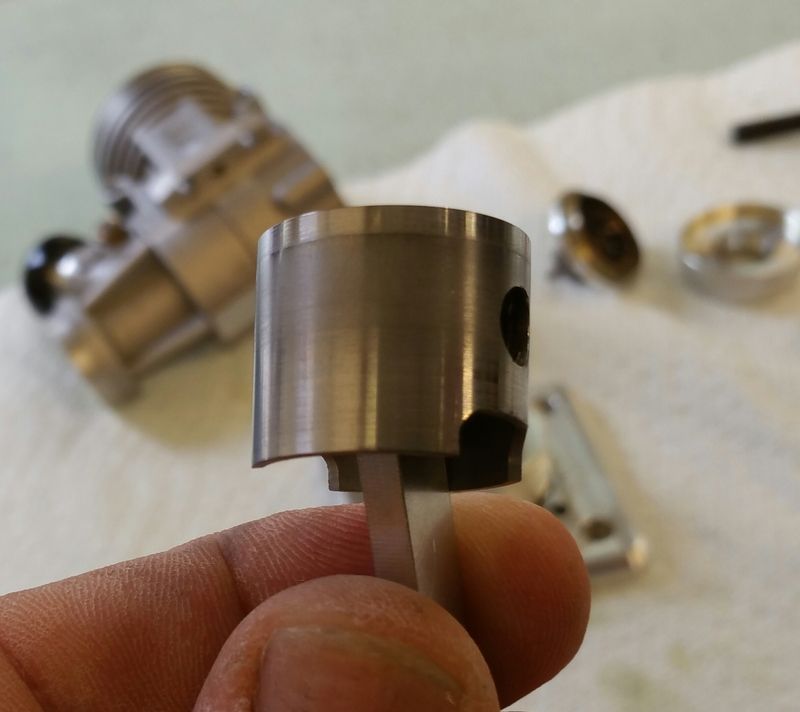

Reading pistons.

The piston will tell you a lot about the performance or happiness of your motor. Here's an example beit an fai motor of the pinch ring and the fit between the piston and liner. Ideally you want color on the exhaust side of the piston and little or no color on the intake side. This is a visual of the post before this one about the piston fit and the piston still sealing until the exhaust port.

If the piston fit was too loose or the taper of the liner was off or the motor was running hot which is the most common cause you get a fit like this.

The blow by all the way around means the hot gasses were passing the piston before the exhaust port opened. This causes hot gasses to make their way back into the intake ports causing the intake charge to enter the cylinder pre heated. This makes a bad situation worse by causing a lean run. A motor running hot can be caused by too much prop loading the motor down. Over compressed and not letting it unload even though ground rpms are good. Ignoring mandatory breakin procedure or in this case leaking plugs.

Side note on the bottom pic and breakin procedures. That piston saw two 750cc tanks on the stand, then one flight to find the needle " it went 59 sec" the next flight it gave all it had and set the FAI world record 55.32 then two more flights at 58 seconds. Randy and I believe the last two flights caused the premature death of this piston as the plugs were leaking causing it to run lean. Had the plugs not leaked it still wouldn't have lasted as long as it would have being properly run in.

The piston will tell you a lot about the performance or happiness of your motor. Here's an example beit an fai motor of the pinch ring and the fit between the piston and liner. Ideally you want color on the exhaust side of the piston and little or no color on the intake side. This is a visual of the post before this one about the piston fit and the piston still sealing until the exhaust port.

If the piston fit was too loose or the taper of the liner was off or the motor was running hot which is the most common cause you get a fit like this.

The blow by all the way around means the hot gasses were passing the piston before the exhaust port opened. This causes hot gasses to make their way back into the intake ports causing the intake charge to enter the cylinder pre heated. This makes a bad situation worse by causing a lean run. A motor running hot can be caused by too much prop loading the motor down. Over compressed and not letting it unload even though ground rpms are good. Ignoring mandatory breakin procedure or in this case leaking plugs.

Side note on the bottom pic and breakin procedures. That piston saw two 750cc tanks on the stand, then one flight to find the needle " it went 59 sec" the next flight it gave all it had and set the FAI world record 55.32 then two more flights at 58 seconds. Randy and I believe the last two flights caused the premature death of this piston as the plugs were leaking causing it to run lean. Had the plugs not leaked it still wouldn't have lasted as long as it would have being properly run in.

And I said, here am I send me.

- AlexVazquez

- Super Contributor

- Posts: 63

- Joined: Tue Feb 24, 2009 1:00 pm

- Location: GUADALAJARA, JALISCO, MEXICO

- Contact:

Re: Latest and greatest timing and deck height?

Thank you Rocket, all the information is great!rocket wrote:Steve, these motors are cooled by intake fuel on the bottom end and air on the topend. The circuit board adheres to epoxy better than aluminum and has nothing to do with cooling or insulation.

Alex, the fits of the piston and liner have to do with expansion when the parts are at operating temps. Ideally you want the piston to seal when hot at the opening of the exhaust port on the way up, at the same time you don't want it still biting as it passes the exhaust port on the down stroke. This extra friction is detrimental to rpm and horsepower.

The "ramp" is witchcraft. Some believe it's a benefit and will give you an edge, some think it's a flying broom. Me... ehhh, I wouldn't know if it's there or not unless I looked. To qualify that, in FAI I've seen stock motors go 55 sec and fully worked motors with ramps go 55 sec.

Pylon Racing Mexico

NMPRA 30y

D9 VP

NMPRA 30y

D9 VP

- AlexVazquez

- Super Contributor

- Posts: 63

- Joined: Tue Feb 24, 2009 1:00 pm

- Location: GUADALAJARA, JALISCO, MEXICO

- Contact:

Re: Latest and greatest timing and deck height?

Regarding the propeller and engine performance, I have observed in my few experience (I’m somewhat new with pylon racing settings), that at high rpm (26.5-27 K) in ground you may not reach good performance in the air. I’m not sure where is the best rpm performance range for Nelson engine and I think this also must be variable at different settings, what I’m sure is that all combustion engines gains power and torque with more rpm but this is not unlimited, at some point the engine performance breaks down (example at engine curve graph). By the way, is somewhere a nelson performace curve or someone have made by her own and may want to share?

I’ve chosen my propellers pitch to see at ground between 24-25.5 Krpm, when I obtain lower rpm then I decrease pitch, and when I reach higher than 25.5K I add pitch. Am I right? I'll be glad reading your opinions

Alex

I’ve chosen my propellers pitch to see at ground between 24-25.5 Krpm, when I obtain lower rpm then I decrease pitch, and when I reach higher than 25.5K I add pitch. Am I right? I'll be glad reading your opinions

Alex

Pylon Racing Mexico

NMPRA 30y

D9 VP

NMPRA 30y

D9 VP

Re: Latest and greatest timing and deck height?

Alex, I few pages back we discussed what's the best rpm on the ground to get the most speed in the air. 28.5k It's believed that's the top of the motors horsepower/torque curve. It's also believed that the motors gain 3k in the air from max ground rpm. So, 25.5 otg should be ideal.

And I said, here am I send me.

- AlexVazquez

- Super Contributor

- Posts: 63

- Joined: Tue Feb 24, 2009 1:00 pm

- Location: GUADALAJARA, JALISCO, MEXICO

- Contact:

Re: Latest and greatest timing and deck height?

Thank you Rocket!

Pylon Racing Mexico

NMPRA 30y

D9 VP

NMPRA 30y

D9 VP

Re: Latest and greatest timing and deck height?

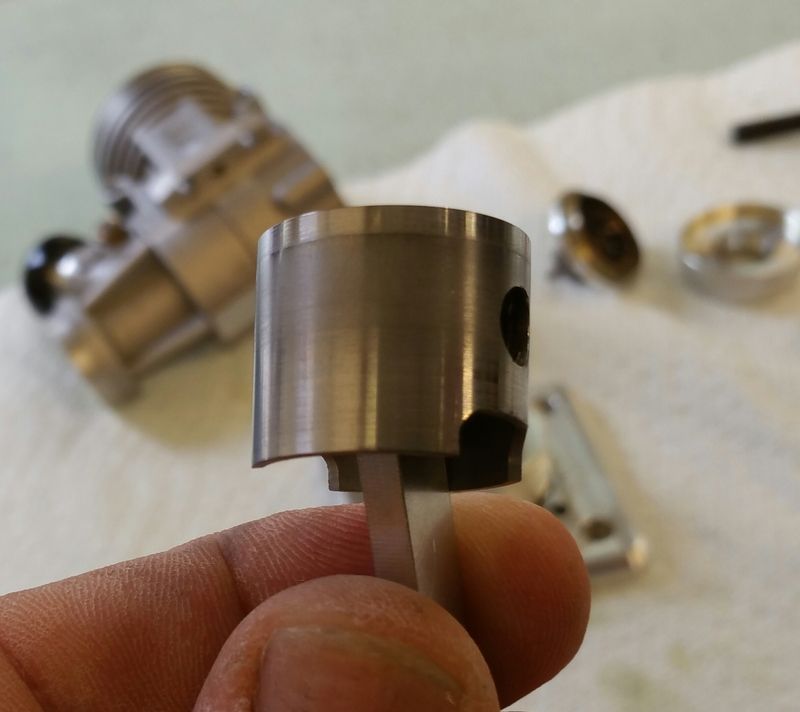

Incase this is illegal I'll leave it on this thread. Some may take offence to "metal" being removed. That being said there are NO performance mods being done to the motor other that re furbing the fits.

The piston has a nice pinch ring even though it got hot a few times. The liner has a wear band as well. We're going to clean them up.

Using mothers mag and aluminum polish, clean up the piston sides and top. Not polishing it to a mirror but just cleaning up the carbon.

The piston has a nice pinch ring even though it got hot a few times. The liner has a wear band as well. We're going to clean them up.

Using mothers mag and aluminum polish, clean up the piston sides and top. Not polishing it to a mirror but just cleaning up the carbon.

Last edited by rocket on Mon Oct 31, 2016 2:35 pm, edited 1 time in total.

And I said, here am I send me.

Re: Latest and greatest timing and deck height?

With the liner cut a piece of 1500 or 2000 grit wet dry sandpaper. Using a finger inside the liner roll it back and forth on a flat corner of a tabletop or in this case a glass countertop. All the while moving the Sandpaper in and out, applying light pressure form a crosshatch.

.

.

.

.And I said, here am I send me.

Re: Latest and greatest timing and deck height?

I use brake cleaner to degrease the parts, then with them dry slip the piston up into the cylinder. Applying pressure until it stops. Now using a depth micrometer or the calipers measure the depth. Anything more than 200 thou still holds promise.

Last edited by rocket on Mon Oct 31, 2016 3:31 pm, edited 2 times in total.

And I said, here am I send me.

Re: Latest and greatest timing and deck height?

Reassemble after a good cleaning. Cylinder, Piston and pin, crank pin and rod get castor. All uprpose lubricating oil on the bearings and crank.

After run oil and the great debate about it

The oil in the pic comes in spray can, you can saturate the piss out of the motor, and, it will cover ALL the metal inside. Not like putting a few drops of whatever with cheese after run. When I pulled this motor apart I was reminded why I don't use "drops" of oil. Here's some pics showing what drops of oil do in your motor. There exactly that, drops. They don't and in most cases won't mix with the residual fuel left in the motor. And, it won't lubricate the steel bearings or crank.

After run oil and the great debate about it

The oil in the pic comes in spray can, you can saturate the piss out of the motor, and, it will cover ALL the metal inside. Not like putting a few drops of whatever with cheese after run. When I pulled this motor apart I was reminded why I don't use "drops" of oil. Here's some pics showing what drops of oil do in your motor. There exactly that, drops. They don't and in most cases won't mix with the residual fuel left in the motor. And, it won't lubricate the steel bearings or crank.

Last edited by rocket on Mon Oct 31, 2016 3:33 pm, edited 2 times in total.

And I said, here am I send me.